- New Products

- AP Racing Big Brake Kits

- AP Racing Brake Discs

- AP Racing Brake Calipers

- AP Racing Master Cylinders

- Essex Brake Bundles (upgraded pads, lines, fluid, discs that work with OEM Calipers)

- Brake Pads

- Brake Fluids

- Spiegler Brake Lines

- Tools, Temperature Indication and Protection Products

- Wheels

- Suspension

- Apparel and Merchandise

- Formula SAE

- Clearance

AP Racing by Essex Brake Kit (Rear 9541/380mm)- Jeep Wrangler JK

Part #: 20.01.10017

Brand: Essex & AP Racing

Complete rear AP Racing by Essex Brake Kit for the Jeep Wrangler JK

Key features and benefits:

- Reduces stopping distances by as much as 10% vs. OEM brakes (15+ feet from 60 mph!)

- Adding large and heavy wheels and tires will not diminish our AP Racing brake system's performance

- Allows for towing max loads without brake fade, even after repeated stops

- Huge discs and pads cut brake running temperatures in half vs. stock, which means zero fade and a much longer service life

- Incredibly stiff six piston calipers reduce compliance and flex while dramatically improving brake pedal travel, feel, and overall vehicle control

- Calipers include dust boots for durability in harsh conditions and are available in a high-quality red, black, or silver painted finish

- Pistons sized properly to maintain brake bias and work with the OEM master cylinder and ABS system

- Designed to mate with our matching front AP Racing Road Brake Kit

- Retains full function of OEM parking brake

Show All vehicles this product fits

Application: Road & Track

Jeep Wrangler JK: The case for bigger brakes

The Jeep is an American Icon along the lines of Apple Pie or Baseball. It is a unique vehicle that elicits joy from its incredibly diverse owner base for a wide variety of reasons. Students love how cool their Jeep makes them look vs. the econoboxes their peers drive. Parents love packing their kids into a topless Jeep for an after-dinner ice cream. Adventurous Jeepers love traversing a mountainside or trying to get their Jeep stuck in the mud, while retired executives view the Jeep as an opportunity to recapture a piece of their youth. Lifting, cruising, bogging, or crawling…however you plan to use it, the Jeep has you covered. In summary, there are a lot of reasons to love the adaptable Jeep and the lifestyle enhancement it can provide.

However, there is one aspect of the Jeep that doesn’t get much love: the brake system. The internet is riddled with bitter complaints about the Jeep’s stock brakes. Some of the more common offenses include:

- Inability to slow or stop when running large wheels and tires

- Brakes that randomly lock or freeze

- Overheating when towing a camper

- ‘Warped’ discs that shake violently under braking

- Pulling to one side while braking

- A soft brake pedal that goes to the floor

- Inexplicable brake squeal or grinding

- Puny and bland appearance behind aftermarket wheel

Essex is pleased to announce that our AP Racing by Essex Brake Kit for the Jeep JK eradicates every problem, issue, or concern on the above list! Our new kit is packed full of technology provided by the global leader in brake systems, AP Racing. Since supplying the brakes that secured their first Formula 1 victory in 1938, AP Racing has been at the forefront of brake technology, winning championships in a diverse array of off and on road arenas such as DAKAR, the World Rally Championship, open wheel, sportscar, and armored vehicles. Their brake packages are also original equipment on some of the most prestigious brands in the world such as Bugatti, McLaren, and Lotus.

What typically causes Jeep brake problems?

Just about all the issues on the bullet list above pertain to heat. Heat reduces brake system effectiveness in numerous ways and overheating any one component in the brake system impacts the others. Brake discs, pads, and/or fluid can all overheat and cause a considerable degradation in performance. Let’s look at a few common scenarios:

Repeated stops- While tires are what technically stops your Jeep, your brake system’s role is to transform the kinetic energy of the spinning discs into heat. OEM brake systems are designed to operate in a typical commuting environment, which means they operate effectively with the OEM wheels and tires for a limited number of stops. As the number of stops increases, so does the amount of heat that is poured into the brake discs, and subsequently the brake pads and fluid. If the discs are not massive enough to hold considerable heat, or if their design is not efficient enough to flow a substantial amount of cooling air, they will potentially overheat both your pads and fluid. Long hill descents that require repeated braking are a common scenario in which stock brakes cannot adequately store and shed enough heat to prevent performance degradation. Longer stopping distances, a pulsating brake pedal, or a soft brake pedal all indicate that the brake system does not have enough thermal capacity to manage the load being placed upon it.

Greater vehicle mass- Increasing the mass of your Jeep itself or towing something behind it is another common way to degrade brake performance. Front and rear steel bumpers, brush guards, tire carriers, roof racks, and huge wheels and tires can easily add several hundred pounds to your Jeep’s curb weight. Compound those increases while also toting a travel trailer, and you really have a recipe for overheated brakes!

Increase in rotating mass- Not only do huge wheels and tires add static weight to your Jeep, but they will also wreak havoc on your brake system once they start spinning. The reason for this is that you are adding mass farther away from the central pivot point (hub) of the wheel. In other words, you are increasing your moment of inertia. Not only will your Jeep accelerate more slowly, but it will also become significantly more difficult to slow and stop. The larger and heavier your wheels, the more difficult it will become for you to stop.

Hard tires with a small contact patch- Additionally, you may be decreasing the amount of friction your tires can generate with the road if you switch to a harder rubber compound or a smaller contact patch vs. your stock tires (knobby style tread vs. treadless for example). Keep in mind that the less friction your tires generate with the driving surface, the longer your stopping distances will be.

Brake pads with a low max operating temperature- Every brake pad compound has a maximum temperature at which it can generate friction. Once that temperature is exceeded, the pad is no longer able to produce friction. OEM pads are developed to a price point and are designed to work well for a few consecutive stops in stock trim. Repeated stops, increased curb weight, towing, and larger wheels and tires will all push the stock pads past their maximum operating temperature, leading to what is called ‘pad fade’. The only solution is to run a pad with a considerably higher maximum operating temperature (MOT).

Brake discs without enough thermal capacity or cooling- Once a Jeep is modified or used in any of the ways previously discussed, it is easy to exceed the thermal constraints of the OEM brake discs. They have neither the mass nor cooling capacity to work effectively under increased loads. The only solution is to add brake discs that can absorb, store, and efficiently dissipate more heat.

Brake fluid with a low boiling point- Once the brake discs, pads, and calipers are overheated, the brake fluid is never far behind. If the fluid’s boiling point is exceeded, small air bubbles form inside the brake lines. When you step on the brakes, those bubbles compress, creating a soft brake pedal and limited force input. The only solution is a brake fluid with a higher boiling point.

Budget brake calipers that lack stiffness- ‘Price point’ calipers that lack stiffness are deformable with enough pressure and heat. Deformable calipers means that your pads no longer make true contact with your brake discs, which leads to pad taper, premature pad wear, and a spongy brake pedal. When a caliper deforms, its response time lowers and there is a lag between the time you press the brake pedal and when the pistons press the pads into the disc.

How will our brake kit solve your brake problems?

- Larger, incredibly efficient brake discs that can absorb and flow far more air than the stock units

- Huge brake pads that absorb and spread heat more effectively, and that have a far higher maximum operating temperature than stock

- Gigantic six and four piston AP Racing calipers that are incredibly stiff and reduce system compliance

- Superior brake fluid with a high boiling point

How do we know our brake system will solve your brake issues?

Because we tested it, and our system has been proven countless times! Essex is AP Racing’s exclusive North American importer and distributor, providing brake solutions for everything from Miatas to the entire NASCAR Cup field. We have been designing and supplying elite-level brake upgrades for forty years, and every weekend our brake systems are put to the test at a racetrack near you (and typically come out victorious). Since our Jeep JK system was one of our first forays specifically into the off-road world, we’ve spent some additional time testing prior to our kit’s release.

Testing, testing, 1, 2, 3...

Prior to the launch of our system, we spent a considerable amount of time conducting instrumented testing on both the road and a closed course. The video below shows some footage from one of our test sessions at the Michelin Laurens Proving Grounds in Mountville, SC. This test was designed to compare the durability, repeatability, and response of our AP Racing by Essex Radi-CAL Brake Kit vs. the OEM Jeep JK brakes as we conducted stops from 60 mph. The Jeep being tested has 20” wheels with 35” Fuel tires installed. Outside temperature was 45°F for the OE brakes and 52°F with the AP/Essex brake system. The brake fluid used was AP Racing Factory R DOT 5.1. An oval was laid out within the confines of a 400’ x 1,400’ flat area, with brake zones at the far end of each straight. Brake events were conducted repeatedly from 60 mph until clear brake degradation was noted. The comparative results shown below were quite eye-opening!

|

|

Brake |

OEM |

AP Racing |

|

|

|

Characteristic |

Events |

Brakes |

by Essex |

Improvement |

Notes |

|

Stopping Distance (in feet) |

1-10 |

190.1’ |

174.1’ |

16.0, 9.2% |

|

|

11-14 |

214.3’ |

185.5’ |

28.8, 9.9% |

||

|

Pedal Travel (in inches)* |

1-10 |

3.15” |

1.67” |

47% reduction |

|

|

11-14 |

3.32” |

1.84” |

45% reduction |

OEM bottomed |

|

|

Temperature Rise (°F) |

1-10 |

1055°F |

509°F |

52% lower |

|

|

11-14 |

1136°F |

610°F |

46% lower |

||

|

Response / Activation (in feet) |

1-10 |

42.0’ |

33.1’ |

8.9’, 21% |

Distance before deceleration |

|

11-14 |

43.9’ |

34.0 |

9.9’, 23% |

|

|

|

*Measured above the foot. Actual foot travel is greater. |

Driver comments and other observations:

The AP/Essex system provided much more confidence. Vehicle direction was also more stable and ABS intervention was not as rough. The driver maintained greater control. After cooling down, the brake pedal with the OE brakes was not as firm as before the test. An obvious degradation was noticed. After cooling down, the brake pedal with the AP/Essex brakes was not noticeably different than before the 24-brake event test.

Testing was stopped after 24 brake events with the AP/Essex system because the system was still performing consistently, but the driver’s foot was starting to hurt from the day of hard braking with soft-soled racing shoes. Performance well beyond the OE system was proven and it was becoming hard for the driver to produce repeatable brake pedal force application.

Visual inspection of the front and rear AP/Essex systems revealed minimal pad wear and no visible damage.

Interpreting the Data

So what can we derive from the test data? Quite a lot!

- Stopping distances- Stopping distances with the AP Racing brakes installed were approximately 10% shorter than they were with the stock brakes. Improvements of 16-29 feet may not sound like a lot at first glance, but what if there was someone pushing a shopping cart across the street in that area? Stopping shorter means staying safer, and our AP Racing by Essex Radi-CAL Brake Kit will shorten your stopping distances regardless of how many repeated stops you do.

- Pedal travel- A long mushy brake pedal severely limits the driver’s ability to control the vehicle. With the stock brakes, the brake pedal bottomed out, and the driver could not add enough force to even activate the anti-lock brake system! Conversely, a high, hard pedal allows the driver to easily modulate the brakes and control the vehicle. Our AP Racing system provided a consistent pedal that allowed the driver to easily adjust their force input to maintain proper control of the brake system and the vehicle.

- Temperature rise- The AP Racing discs only got about half as hot as the OEM discs during all stops! If you remember the first part of this article, heat is the number one enemy of brake systems that leads to a laundry list of potential brake problems. Less heat means more durability and less wear, more consistent performance, less propensity for fade, greater safety and control, and lower long-term running costs.

- Response time- The stiff AP Racing calipers and Spiegler stainless steel lines in our AP Racing system reduced system response time by nearly 25% vs. stock! That means when the driver pressed the brake pedal, the AP Racing calipers clamped the discs much more rapidly than the OEM calipers did. Superior response ultimately means greater driver control, shorter stopping distances, and improved safety.

Summary

Our AP Racing by Essex World Radi-CAL II Brake Kit is far superior to the OEM brakes in every conceivable manner short of fitting inside small wheels. It activates much more rapidly and allows you to stop in considerably shorter distances, as many times in a row as you need to do so. It provides a much higher, harder brake pedal that can be easily modulated while retaining proper ABS function, while every brake component will run at about half the temperature of its OEM counterpart. That means a huge increase in durability and longevity. Not only does our kit look incredible, but it will dramatically enhance the performance envelope of your Jeep.

What's In The Box?

- One pair AP Racing CP9541 World Radi-CAL II four piston calipers

- One pair 380x28mm AP Racing J Hook discs with fully floating 6061 hard anodized aluminum hats, 48 cooling vanes and attachment hardware

- One pair caliper mounting brackets and hardware

- One pair Spiegler Stainless Steel Brake Lines with abrasion resistant coating

- One set of Ferodo DS2500 Brake Pads

- Detailed installation instructions

- Brake fluid is NOT included with the kit, but Essex strongly recommends AP Racing Factory R DOT 5.1 fluid in this application

Radi-CAL Calipers

“Radi-CAL” is a blanket term used to describe AP Racing’s patented asymmetrical brake caliper design. Radi-Cal technology is grounded in Computer Aided Design (CAD) and Finite Element Analysis (FEA), and allows for organic, alien-looking designs that are a radical departure from conventional caliper designs of the past. Radi-CAL's are widely considered the pinnacle of current brake caliper technology. Since their inception in 2007, these revolutionary calipers have amassed a lengthy string of race victories at all levels of professional motorsport, while redefining brake performance expectations. For more details on the design concept and what these calipers have achieved in professional racing, please visit our blog and read The AP Racing Radi-CAL Story.

The key benefits of the Radi-CAL design:

- Massive Stiffness Increase- A 30+ % increase in both static and dynamic stiffness vs. conventional calipers allows for far less deflection under load, which means superior pedal feel & modulation, more even pad wear, and longer caliper service life.

- Considerable Mass Reduction- Removing all extraneous caliper mass lowers the caliper weight, despite the huge stiffness increases.

- Optimized Airflow- Air moves around and through the caliper more efficiently, providing superior heat evacuation and cooling.

- Efficient Packaging- The asymmetric caliper profile allows the caliper to fit into tighter spaces.

CP9541 World Radi-CAL II (WRII)

It took eight years, numerous generations of the design concept, and advancements in manufacturing techniques, but the Radi-CAL finally evolved into a viable solution for enthusiasts of all levels and budgets. While many products are supposedly born in racing, there can be no doubt about the Radi-CAL pedigree. These calipers are direct descendants of the current crop of F1 and NASCAR Cup calipers. They don't look ordinary, because they're not ordinary. They're the epitome of racing design: elegant, sparse, and brutally effective. And while they embody and employ the Radi-CAL design philosophy of the past, they also add some outstanding new features that enhance their practicality, convenience, and appeal. Quite simply, they are the most technologically advanced brake calipers that have ever been within the common enthusiast's grasp.

Radi-CAL = Massive Dynamic Stiffness Increase

Over the years, many different strategies have been employed to shrink the brake caliper footprint while maintaining adequate stiffness: More robust caliper bridge designs, two-piece calipers with steel through-bolts, exotic materials (i.e. Beryllium, MMC), forging rather than casting, monobloc design, etc. All of these innovations pushed calipers towards becoming lighter, smaller, and stiffer. However, until the advent of the Radi-CAL, the same basic rectangular, boxy shape remained the accepted standard.

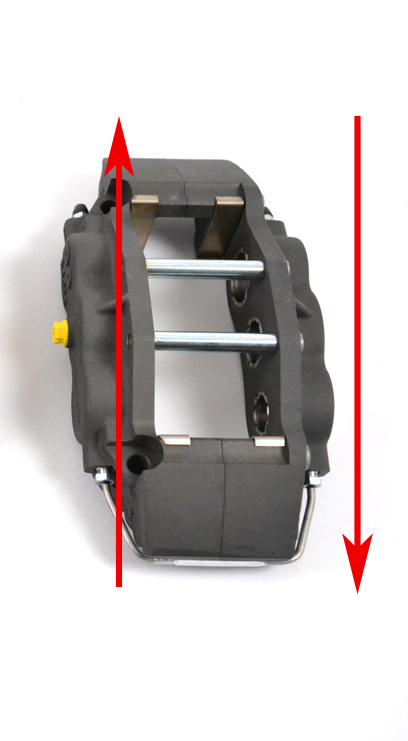

Is a rectangular box really the most appropriate and efficient shape for a brake caliper? AP Racing has now proven that it is not. As a brake caliper clamps brake pads against a spinning disc, a tremendous tangential friction force occurs between the pads and the spinning disc. In other words, the caliper is pulled strongly in the direction of the spinning disc, as represented by the downward pointing arrow on the right side in Figure 1 below. The caliper resists that force via the spindle hard mounting points, depicted by the upward arrow on the left. The dynamic load placed on the caliper twists or pulls the caliper into a parallelogram shape.

Figure 1

The dynamic force exerted on the calipers during a

braking event is the key to the magic of the Radi-CAL design philosophy.

Brake calipers of the past were designed to some extent in relative

isolation from the forces that they were attempting to combat. They

were designed to be the stiffest box possible while resting on a table,

with much of the caliper mass residing at either end.

The

Radi-CAL is dramatically different because it was deliberately designed

around the braking event forces that will be acting upon it.

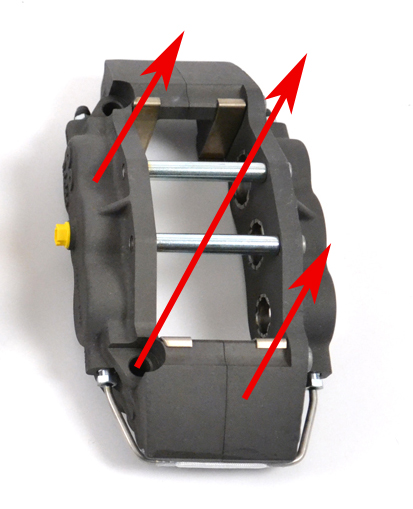

This is achieved by optimally distributing the body mass of the caliper

on a diagonal, rather than at the two caliper ends. As such, the forces

dynamically acting on the caliper are supported by the caliper mass,

rather than what historically has been an empty box (see Figure 2

below). At the same time, this also allows for a significant reduction

in overall mass, because all non-essential, non-load-bearing caliper

body material is removed. So in the case of the Radi-CAL,

it's not just about the material that is put into the caliper, it's about the material that is taken away!

What does the above mean for you, the driver? It means a significantly firmer brake pedal with superior modulation under all conditions. It also means more even pad wear with less tapering, and a longer caliper service life.

Figure 2

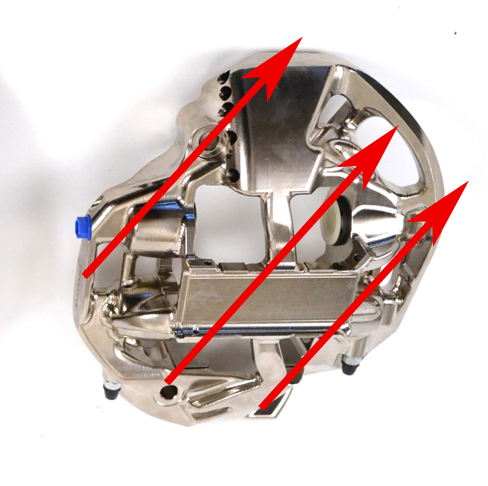

Radi-CAL= Lightweight, Compact Design with High Airflow

As mentioned above, the Radi-CAL design philosophy is just as much about what isn't there, as it is about what is there. The Radi-CAL design relocates caliper mass, creating voids that would traditionally not be located where they are. As such, considerable mass is removed from the caliper body, and the entire envelope of the caliper is optimized. The result is a lightweight and compact footprint, with pistons and brake fluid pathways that have far more surface area exposed to cooling air. The result is lower overall brake system operating temperatures and lower weight.

Many of our clients want to hop in their road car and drive to the track for the occasional HPDE on their OEM wheels and tires. The AP Racing World Radi-CAL II was designed with OEM wheel fitment in mind, and our brake packages won't have much trouble clearing many of today's 19" and 20" OEM wheels. Downloadable wheel fitment templates are available for every kit we offer, so be sure to check your specific wheels prior to ordering.

Two-piece, Forged Caliper Body

In racing, the Radi-CAL has traditionally been

machined from a single, solid block of proprietary aluminum alloy

(billet monobloc). With a billet monobloc design, the piston bores and piston seal

grooves can only be machined with a right angle machine tool (the tool

must be inserted up and into the caliper). As one can imagine,

machining away all that material with special tools and multiple

setups to achieve the final form is both time-consuming and costly. As a

result, the price of a billet monobloc Radi-CAL has historically been

prohibitive for anyone outside a professional race team. The World Radi-CAL II however, has been made possible by a newly developed forging process that allows conventional machine tools

to access the piston bores via a direct path. The result is a drastic

reduction in both production time and cost, while still retaining an

incredibly stiff form. Forging also offers a more uniform grain structure than an equivalent cast part, providing greater strength and stiffness, which further contributes to superior pedal feel.

Elegant Red, Black, or Silver Painted Finish

The World Radi-CAL II is available in elegant red, black, or silver paint, offering hue options that won't clash with your vehicle's paint scheme. AP Racing conducts an extensive battery of durability testing on their painted finishes. The calipers are baked to extreme temperatures to simulate track use, sprayed with salt, and generally mistreated and abused before being approved for deployment. That means their beauty will not only surprise you when you pull them out of the box, but they will continue to look great for many years to come.

The overall finish quality of the World Radi-CAL II is unrivaled. Unlike some competing products that are assembled first then painted, The WRII is carefully masked and painted prior to assembly. They don't have over-spray on the dust boots, crossover tube, and bleed screws, and the result is a far more polished final appearance. Closeup photos also reveal the premium quality of AP's raw forgings, which lend themselves to an incredibly smooth final finish coat with relatively little orange peel.

AP Racing World Radi-CAL II finish

Competitor's painted caliper finish

Standard Anti-rattle Hardware

When you take your car out on date night, you don't want to hear rattling noises emanating from your brakes. All WRII calipers come with anti-rattle spring clips as standard. The spring clip places downward pressure on the top of the pad to dramatically reduce its movement both laterally and vertically. The result is a very OE-like experience, and no funny looks from your date when you pull up to the valet.

Piston Dust Boots for Dirt and Inclement Weather Protection

If you drive your car through four seasons, dust boots can come in handy. If you run calipers without dust boots, dirt and grime can accumulate on the sides of the caliper pistons. While that in itself is a problem, it can create a problem when it's time to change pads. In order to insert a fresh set of pads at full thickness, the pistons must be pushed back into the caliper. If the pistons are pushed back into the caliper with debris on them, the internal piston seals can be cut or deformed, resulting in a leak. One can either carefully wipe the pistons before retracting them into the caliper (as is the case with a competition or racing brake kit), or you can run dust boots on the pistons, which avoids the issue all together.

Below is what a dust boot looks like when the piston is extended. It keeps the walls of the piston covered/protected as the piston extends.

Simple Pad Change with Two Bolts

Changing pads is quick and easy with AP's World Radi-CAL II. AP’s bridge bolts pop out easily with a 6mm hex wrench. It will take you longer to pull off the wheel than it will to change pads. Less time futzing around and more time driving= fun!

Pistons Sized Specifically for Your Car

The piston sizes in our systems are specifically chosen to closely mimic the OEM brake torque on a given axle. As such, our front systems can be bolted to otherwise stock cars with no ill-effects, negative impact on ABS, etc. The vehicles stock master cylinder can remain, as can the OEM rear brake system.

High Volume Brake Pads

In a pure racing brake system, disc weight is a crucial consideration. A disc's radial depth (height of the disc's swept area) has a significant impact on how much it weighs. As such, racing discs typically have a radial depth no larger than 54mm. If you examine one of our Competition Brake Kits, or any of our professional racing systems, you'll find that none of the discs or corresponding pads have a radial depth taller than 54mm. You'll also find that those discs typically have an extremely high internal vane count and/or a special vane design such as AP Racing's Sinusoidal 'S' Vane pattern, designed to maximize airflow. These disc designs use the principle of convection to evacuate heat (if you envision the flow of air through the discs as a liquid). In racing, the overall disc mass can be reduced because the cars are consistently reaching speeds at which enough air is flowing through them to leverage these design features. The driver stands on the brakes for a few seconds, and then s/he is immediately hurtling towards the next turn while pushing a large volume of cooling air through the discs.

So what does that have to do with brake pads? A pad's volume is equal to its length x height x thickness. The greater the volume, the more mass it has to absorb heat. Without adequate mass, a brake pad quickly becomes heat-soaked, reaches its maximum operating temperature, potentially fades, and burns up very quickly. Since a race car may need to run up to 25 hours straight on a single set of brake pads, a considerable amount of pad mass is required. Unfortunately as described above, a racing disc's short radial depth substantially limits the pad height. That means greater pad volume must be achieved via increased pad length or thickness. If the pad is too long, the backing plate could warp, the pad material could fracture, and pad taper might become problematic. That's why eight piston calipers with a single pad per side never seem to work very well. The only remaining option to increase pad volume is via increased thickness, and in pro racing we use pads up to 30mm thick. The problem with using extremely thick pads however, is that they require a very wide caliper to accept them! If you look at a Competition Radi-CAL vs. a Road Radi-CAL, you'll note that the Competition Radi-CAL will almost always be wider. While wide calipers fit well on a race car designed to accommodate them, they don't always integrate smoothly on a road car. That means a different methodology must be employed to keep brake temperatures and wear rates under control on road cars, which won't be traveling at 100mph+ most of the time (unless the owner wants to be arrested!).

The solution to gain a large amount of pad volume while taking packaging requirements into account is a four piston caliper with a pad that is both longer and has a fairly tall radial depth. The heat is spread over a larger surface area, relying on the principle

of radiation to remove heat into the air surrounding the disc.

With the CP9541 World Radi-CAL II, our rear pad has more volume than the front pads in many of our competitors' calipers, as well as many OEM front calipers!

So what does the above mean for you? It means that even though our road brake system is designed around narrower Radi-CAL calipers than we usually employ in racing, the large pad volume will help ensure that it's still going to be incredibly capable and durable when pushed to the limit. The large pads mated to our chosen discs will shrug-off a massive wallop of deceleration and its resulting heat. Our Road Kits are fully capable of handling the occasional track day without being stressed. It also means that the pads and discs are going to last a very long time under light load conditions, like when you're cruising to Cars and Coffee or running the canyons.

Below is a drawing of the pad shape used in the CP9541.

Dimensions= 130.3mm x 81mm x 16.9mm, D55

Ferodo Racing DS2500 Brake Pads Included

You only get one chance to make a first impression, which is why we include a set of Ferodo DS2500 pads in every AP Racing by Essex Road Brake Kit. Although we always recommend using a dedicated race pad for the track, the Ferodo DS2500 is one of the best hybrid street/track pads on the market. It features the moderately high bite and solid fade resistance of a track pad, with the low noise levels and non-corrosive dust of a street pad. During aggressive driving the DS2500 is known for its flat torque curve, which means as temperatures go up, the response through the brake pedal remains consistent. Please visit our Ferodo Racing brake pad page for more details on these fantastic pads.

Spare Ferodo DS2500 pads for the CP9541 World Radi-CAL II caliper can be found here

Discs- AP Racing J Hook

AP Racing J Hook discs have achieved near-legendary status in both professional and amateur racing for their durability and crack resistance. They have been proven time and again, winning many races and championships (ALMS, Rolex, Grand Am, etc. While the discs we're employing in our Road Kits have an impeccable racing pedigree, we've also added some features that will keep them composed and well-mannered on the street).

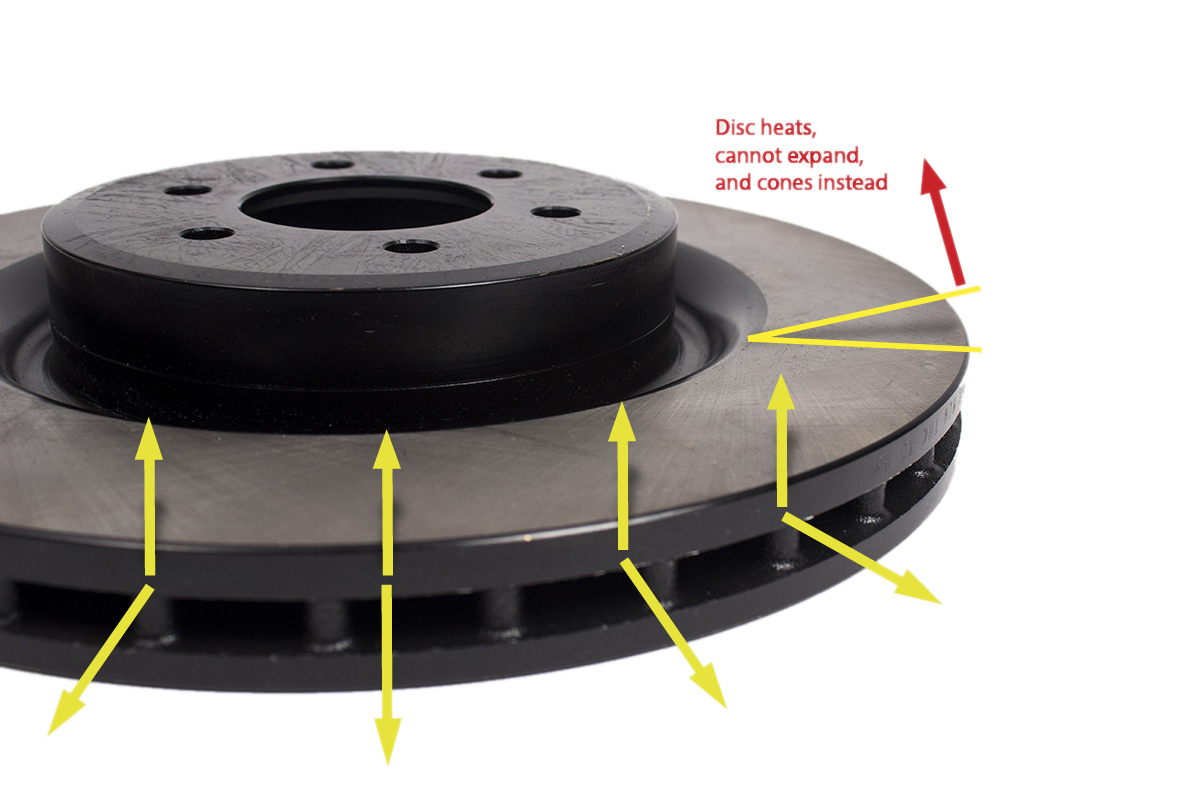

Two-piece Floating Design with Aluminum Hat

As is the case with most metal, iron brake discs grow substantially when heated. As it is heated, a disc expands radially, increasing in diameter and circumference. One-piece disc designs run into problems when this occurs. Look at the picture below and imagine the disc is being heated on the track. As the disc expands, the outer edges of the disc are pulling away from the center of the disc, but there are no built-in provisions to allow for that expansion. The edges of the disc therefore pull, lift, and distort, which is called coning. Now imagine that disc vertical on the car, running in your caliper. Coning directly impacts the brake pads’ contact with the disc, leading to uneven wear and tapering, and even a long brake pedal. Two-piece discs on the other hand, compensate for the expansion of the disc as it heats. This is accomplished by building ‘float’ into either the disc itself, or the disc hat/bell. In this case, the float is in the hat. As the disc heats and expands, the hat bobbins slide in the channels and eliminate stress on the iron disc ring, leading to less distortion and fewer cracks.

Mounting Hardware and Anti-rattle Spring Clips

If you look closely at the mounting hardware we use in our Road Kits, you’ll notice a few details that are often overlooked in lesser products. These components are specially made for their intended purpose. These are not cheap bolts found at your local big box store. They are custom made by AP Racing, and they are of the exact same grade as the components used in OEM applications for Bugatti, McLaren, and Lotus. The spring clips help keep the disc hat and iron ring in alignment, while still allowing the disc to expand and float radially. As an added bonus, they prevent the hat and iron disc from rattling and making noise. You'll also note that the portion of the hat that typically receives the most wear in a float-in-hat setup is reinforced with a stainless steel lining, which reduces wear and extends the life of the aluminum hat.

Hat Design

Floating two-piece discs also have the added benefit of reducing heat conduction to the hubs and bearings, decreasing wear and tear on these costly components. The disc hats themselves are manufactured from 6061 heat-treated billet aluminum, with a hard anodized coating. This material was specifically chosen for its strength at high temperatures, as it will be in direct contact with the searing hot iron discs.

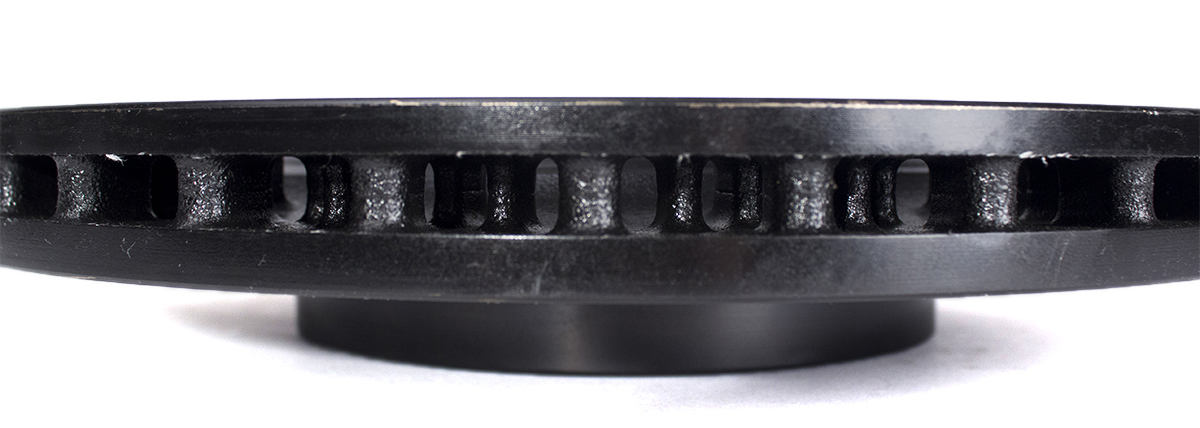

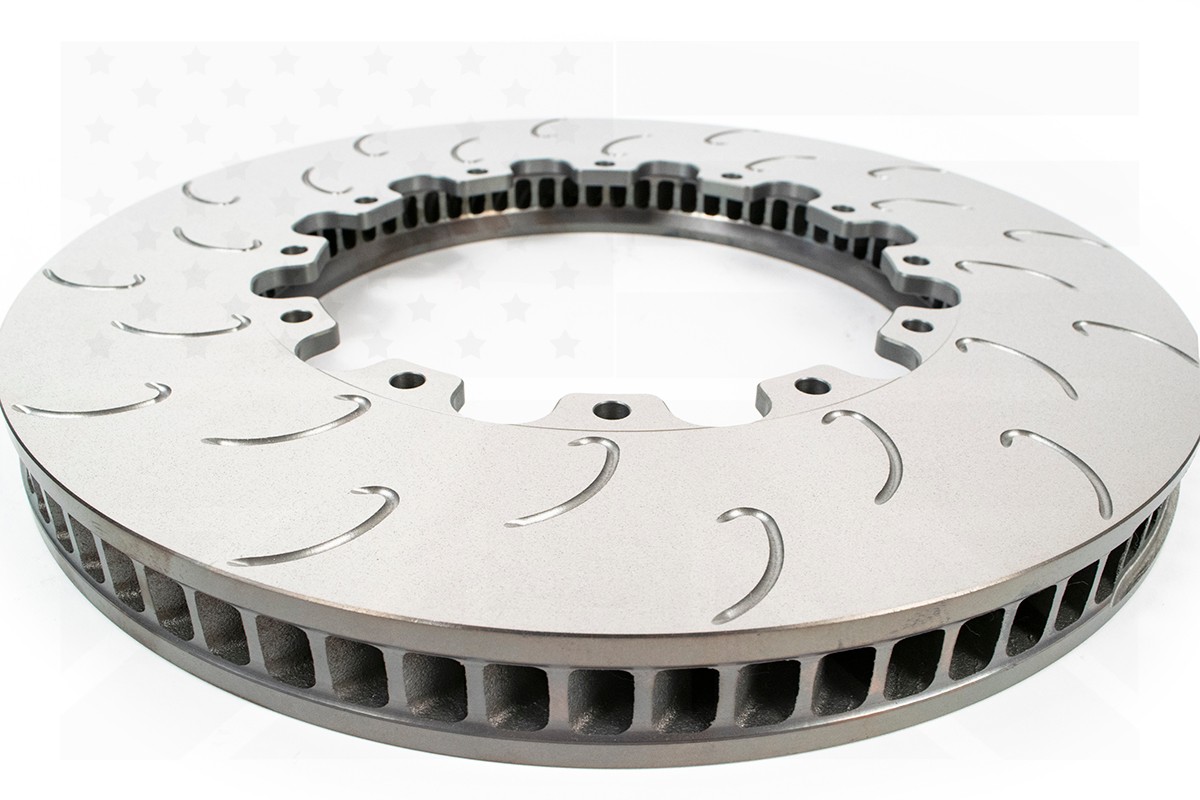

Internal Vane Quantity and Quality

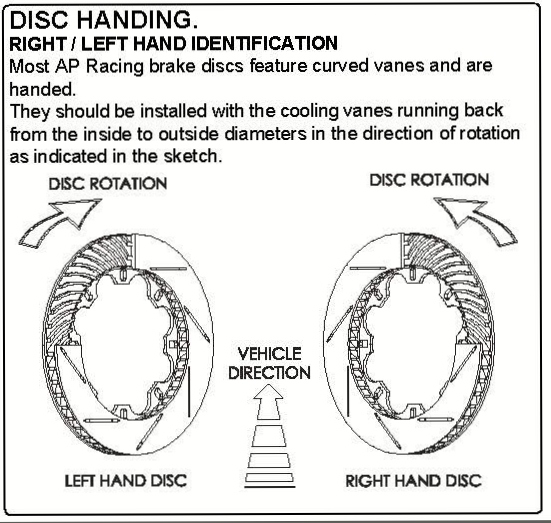

The internal vane design on AP J Hook discs is quite a bit different vs. OEM-style discs and other brands of aftermarket discs. Many OEM discs feature a pillar vane design, which can be thought of as a group of posts or pillars connecting the two disc halves together (see pic below). The pillars are not organized linearly from the outside to the inside of the disc, and turbulence is created as air flows through and among them. Pillar vane discs are therefore not particularly well suited to heat evacuation. The goals of a pillar vane design are disc face stability for low NVH (Noise, Vibration, Harshness), and a low cost of production. Pillar vanes are non-directional, and the same part number is used on both sides of the car (again for cost reduction). Other OEM discs feature a straight, non-directional internal vane. While that type of vane flows more air than a pillar, it does not move nearly as much air as the directional vanes featured in AP Racing's discs. Having directional vanes means that AP Racing discs are handed. There is a unique left disc and a right disc in each pair, and they cannot be swapped from side-to-side on the car. The orientation of the vanes is optimized to spin in a certain direction, pumping the maximum amount of air possible through the disc. The shape of these internal vanes is also optimized to promote smooth airflow.

In addition to having a superior internal vane design, AP Racing discs have far more of them! Most aftermarket discs have 30 to 48 vanes. After extensive CFD and thermal stress analysis, AP designed the J Hook's with a high vane count (typically 60 to 84 depending on application). Having more vanes increases airspeed and heat transfer through the disc, reduces air re-circulation between vanes, and reduces deflection at the disc face. Compared to an OEM-style disc or competitor's 48 vane discs, the 60+ vane discs are less prone to coning, distortion, and cracking, while providing less brake fade, reduced judder, more even pad contact, and a longer service life.

Below is a comparison of a one-piece OEM pillar vane disc and an AP Racing two-piece J Hook. A few things to note in these pictures: The AP Racing disc has a much wider air gap between the disc faces, allowing considerably more airflow into and through the disc. The uniform, directional vane design also contributes heavily to superior airflow.

Most of the cooling air that enters a brake disc comes from the back side of the discs, particularly if brake ducts are being employed. The top disc is an OEM pillar vane. The second disc is an OEM dual-cast disc (which is technically a two-piece disc). The bottom disc is the AP Racing J Hook. Which of these discs do you think will flow the most air? While the OEM discs have narrow inlet port and/or obstructions blocking the disc vanes, the AP Racing disc offers a clear path for cooling air to enter and flow through the disc. The result is significantly cooler discs that are less prone to cracking and wear.

Exclusive AP Racing J Hook Slot Pattern

When you cut a slot or drill a hole in a disc you impact heat transfer. The area around the slot or hole acts as a cool spot when the disc heats up, which is not ideal. Ideally, heat is distributed uniformly around the disc so it can be hit with the cooling air that is pumping through the disc, radiate outwards away from the disc, etc. Cool spots create stress risers and increase the likelihood of the disc cracking. They also cause the face of the disc to distort unevenly, leading to uneven pad deposits, vibration, and judder.

The OEM discs avoid this

problem by simply leaving the face blank. While the risk for NVH goes

down slightly, so does the pad bite and feel of the disc through the brake

pedal. Competitive aftermarket offerings typically have straight slots,

which tend to leave cool spots across the disc face between the slots.

During

exhaustive R&D testing, AP's J Hook design was found to create a

constant pathway of evenly distorted material on the face of the disc.

The hooks are spaced out as evenly as possible both around the

circumference of the disc, as well as from the inside edge (where the

hat attaches) to outer edge, with a slight overlap to promote even heat

distribution/distortion. In addition to reducing cracking, the even

heating of the disc also helps provide an even transfer layer of pad

material on the disc when you bed them in.

Additionally, the J

Hook slot pattern produces a greater number of leading edges for the

pads to bite into vs. a traditional curved slot pattern, and

particularly a plain-faced disc. The

benefits include more even heat distribution, less propensity to crack,

cleaner pad material transfer during bed-in, and more bite.

Complex Metallurgy Developed Through 50+ Years of Experience

AP Racing has been designing brake components for more than 50 years. They've had their components on cars that have won more than 800 Formula 1 races! On any given race weekend, AP J Hook discs can be found on 75% or more of the NASCAR Sprint Cup grid. AP has learned from these experiences and have developed a proprietary iron alloy with extreme durability. They will do exactly what you intend to do with them, regardless of whether that means going out on a date or flogging the hell out of them. The primary objectives with OEM discs are simple: they must be cheap and easy to produce. The design objectives for these two products are vastly different.

Caliper Brackets & Hardware

Caliper brackets for our kit are machined from heat-treated 6061 T6 billet aluminum, and hard anodized, ensuring strength and durability. All included hardware is of aircraft quality, and identical to what we use in professional racing. The brackets also typically include helpful tips for install, such as which direction should be facing the disc.

Spiegler Stainless Steel Brake Lines

Our Road Kits include a set of the highest quality, DOT compliant stainless steel brake lines available. Spiegler lines have a wide range of features not available in competitive offerings. Below are just a few. For complete details please visit the Spiegler page on our site.

|

Feature |

Benefit |

|

All components manufactured in USA and Europe |

Stringent and consistent quality control |

|

Stress-free Torsion Fitting System |

Allows 360 degree rotation of banjo fitting for correct alignment and strain reduction |

|

Abrasion resistant coating/sheath |

Eliminates snagging and chafing |

|

Aircraft quality stainless steel fittings and bolts |

Superior strength, longevity, and safety |

|

Heavy gauge, tightly woven stainless steel braid |

Eliminates line swell, more consistent feel |

|

Du Pont PTFE- Teflon® lining |

Reduces line expansion and provides greater durability |

|

DOT compliant |

Quality assurance, road legal |

|

Full testing battery on all parts, with lifetime warranty |

Purchase and drive with confidence |

Our Jeep JK AP Racing Radi-CAL Brake Kit offers the following benefits:

- Reduces stopping distances by as much as 10% vs. OEM brakes (15+ feet from 60 mph!)

- Adding large and heavy wheels and tires will not diminish our AP Racing brake system's performance

- Allows for towing max loads without brake fade, even after repeated stops

- Huge discs and pads cut brake running temperatures in half vs. stock, which means zero fade and a much longer service life

- Incredibly stiff six piston calipers reduce compliance and flex while dramatically improving brake pedal travel, feel, and overall vehicle control

- Calipers include dust boots for durability in harsh conditions and are available in a high-quality red, black, or silver painted finish

- Pistons sized properly to maintain brake bias and work with the OEM master cylinder and ABS system

- Designed to mate with our matching front AP Racing Road Brake Kit

- Retains full function of OEM parking brake

| Model Year | 2012 | |

| Essex/AP BBK | Jeep Wrangler JK Sport rear | |

| Caliper | AP Racing CP9541 4 piston | OEM 1 piston |

| Weight | 7.1 lbs. | 7.6 lbs. |

| Piston size(s) | 28.6mm x 2 | 48mm x 1 |

| 31.8mm x 2 | ||

| Mounting Type | Radial |

Lug |

| Disc | CP5914-484/485GA | OEM |

| Type | 2-piece floating vented | 1-piece solid non-vented |

| Weight | 16.4 lbs. | 15.35 lbs. |

| Diameter | 380mm | 316mm |

| Thickness | 28mm | 12mm |

| Radial Depth | 55mm | 39mm |

| No. of Vanes | 48 | 0 |

Complete Kit Installation Instructions

Confirmed wheels that fit without a spacer:

How to use the wheel fitment template:

Brake Pads

The available pad compounds that Essex sells for the CP954x caliper

can be found below. Please keep in mind that there are other

compounds available on the market from other manufacturers. The list

below represents only what Essex offers. The pad compounds

are listed from most aggressive to least aggressive.

Ferodo Racing

Below is a drawing of the pad shape used in the AP Racing CP954x World Radi-CAL II

calipers.

Dimensions= 130.3mm x 81mm x 16.9mm, D55

Spare Iron Brake Disc Rings

Driver Side (Left Hand) - AP Racing Part # CP5914-485GA - Essex Part # 20.05.10011

Passenger Side (Right Hand) - AP Racing Part # CP5914-484GA - Essex Part # 20.05.10010

Disc Attachment Hardware

Road System Disc Hardware Kit (enough for 1 disc) - Essex Part # 20.04.40000

Road Brake Kit FAQ

Q: Where can I buy one of your brake kits?

A: Essex sells directly to both retail customers and through an extensive network of wholesale dealers/resellers across North America.You can check our Dealer Locator tool to find a local reseller.The other option is to place an order directly on our website, or call us to place an order by phone at 704-824-6030.

Q: Do Road Brake Kits come with pads?

A: Yes. AP Racing by Essex Road Brake Kits come with a set of Ferodo DS2500 brake pads. Please visit this link for more information on Ferodo.

Q: Do you have a brake pad that works well on both the street and the track?

A: There will always be a compromise when running a pad in an environment for which it was not specifically designed. See the two questions below for more details.

Q: Is it okay to run street pads on the racetrack?

A: No! Street pads are designed to chase groceries, not lap times.If you overheat a street pad beyond its max operating temperature, you risk not only destroying those pads, but your discs as well.Essex always recommends using street pads on the street, and race/track pads on the track. If you must only use one brake pad, the Ferodo DS2500 is your best bet, which is the pad included in our Road Kits. That said, please be warned that the DS2500 does have its limitations when run on the track. They could be prone to fade at extremely high temps, and will wear quickly if they got hot enough.

Q: Is it okay to run race pads on the street?

A: Most race pads are designed to work optimally at high temperatures.As such, they many times don't have good cold bite, making them a poor choice for street use. Even if they do have cold bite, they will likely make a lot of squealing and screeching noises, produce heavy dust, and chew your discs up in a hurry when driven around cold.

Q: How much brake fluid do I need when installing my brake kit?

A:

Essex recommends two 500ml bottles of brake fluid.That will be enough

to bleed the brakes during the initial install, and have a little bit

left over if a second brake bleed is required.

Q: Which brake fluid is best for me?

A:AP Racing offers five different brake fluids to meet all customer needs and budgets. If you're tracking your car regularly, you should be looking at AP Racing R2, R3, or R4. The main difference between those fluids is their boiling points. If you'll only be driving on the street, any of the AP Racing or Ferodo fluids will get the job done. Please check the product page for each to see which best matches your needs and budget.

Q: Is it okay to just buy your front-only brake kit? What about the rears?

A: Our front brake kits are designed to very closely mimic the OEM torque output on the front axle.That is accomplished by carefully sizing the discs and caliper pistons. For example, if we increase the disc diameter in our kit vs. stock, we decrease the overall piston area to produce the same overall torque output as the factory setup. As such, installing our front kit on your car will only have a negligible impact on brake bias. In most cases, the shift in brake bias is only in the several percent range.To put that in perspective, installing a more aggressive brake pad compound in your factory front calipers would typically have a greater impact on brake bias than installing our front kit while keeping the OEM front pad compound.

On most front-engine sports cars, the front brakes are taxed much more heavily than the rear brakes.That's why the front brakes are almost always larger, and why you go through 2-3 sets of front pads and discs for every set of rears you burn through. The fronts do a disproportionate amount of work, and as such, they are the most critical component to upgrade. On many platforms, rear brake upgrades offer diminishing returns.The rear factory components tend to be smaller and lighter than the front components

On a rear-engine car, the rear brakes do a proportionately higher amount of work than on a front-engine car. As such, brake wear tends to be more balanced on the front and rear, and rear upgrades can be more relatively more important to the overall system performance.

Q: Will your brake kit mess with my ABS, stability control, torque vectoring, or disrupt my front to rear brake bias/balance?

A: No! Since our systems closely mimic the factory brake torque output on a given axle as described above, they normally have no substantial impact on ABS, stability control, torque vectoring, etc.The brake pedal will feel much better due to lower overall system compliance, and the brakes will take a far greater beating for considerably longer.

Q: Do I have to modify my spindle or do any fabrication to install your brake kit?

A: In 99% of all cases, no. On a few of our kits you may have to grind down some spindle casting flash to get a caliper bracket to seat properly. This can be done with a hand file or Dremel. You don't need to be an engineer or feel intimidated about installing one of our kits. Since we don't use universal caliper brackets or hats, our kits are all custom creations designed specifically for your car. That means when they are installed properly, they will integrate easily with the vehicle. All of that said, if you have any concerns about doing the job, it will always be safer to have the install completed by a certified mechanic. If you look at the "Wheel Fitment & Installation" tab on the product page, you can download our install manual and see what all is involved.

Q: Do I have to change my master cylinder to use your kit?

A: Absolutely not. Our kits bolt on at the wheel end with simple hand tools. No other modifications are required.

Q: Will your brake kit significantly shorten my stopping distances with all else held equal?

A: No! Tires stop your car. Brakes turn the energy of the spinning brake discs into heat. The primary function of a properly designed big brake kit to withstand the heat encountered during the repetitive and heavy use of the brakes.Anyone who sells you a brake kit specifically to shorten your stopping distances is lying to you.If you want shorter stopping distances, buy stickier tires. If you want your brakes to feel exactly the same on the last lap of the day as they did on the first lap, buy our brake kit.

Q: I saw that your brake kits reduce unsprung weight…will that help me?

A: Yes! Reducing unsprung weight not only improves braking performance, but also translates to superior acceleration and cornering as well. As is the case with switching to a lighter wheel and tire combo, installing a lighter brake package can improve your car's overall performance envelope.

Q: I installed my brake kit, but my pedal is still a bit mushy.Why?

A: You still have air trapped somewhere in your brake system. A closed hydraulic system is based around brake fluid that is not compressible.As such, your pedal should be firm with relatively short travel after install.Sometimes air bubbles get trapped in your system however, and those air bubbles are compressible. During install, moving your caliper around at different angles, or tapping it lightly with a rubber mallet can work the air bubbles out to a bleed screw. Air bubbles also sometimes get trapped in your ABS system. Make sure to cycle the ABS via a scan tool or manually before doing another bleed.

Q: How do I retract the caliper pistons when changing pads?

A: We recommend using a small block of soft wood (pine) covered with a rag or cloth to press the pistons back into the caliper. Make sure no hard or rough surface is making contact with the caliper pistons. Leave a pad in one side of the caliper while pressing all of the pistons on the other side back into the caliper at the same time.

On four piston calipers, some people flip their brake pad vertical and use it to lever the pads back into their bores. We do not recommend doing so, as it may damage the pad, the disc against which you are levering, or the pistons themselves.

Q: Can I use "Speedbleeder" bleed screws in my AP Racing calipers?

A: Essex does not recommend any bleed screw other than the ones that came with your AP Racing calipers (which vary in size & thread pitch depending on the caliper).

Q: Can I get a Road Brake Kit with calipers of a different color?

A: Yes. AP Racing by Essex Road Brake Kits are available with red, black, or silver calipers. Custom colors are not an option.

Q: Are spare parts available and reasonably priced?

A: Being

a company brimming with car enthusiasts, we're very aware of

the long-term running costs of a high-performance vehicle. When we created

our Road Brake Kit product line, availability and long-term

running costs were of paramount concern. We did a couple of things to

address these issues. First we're buying loads of spares and keeping them

on the shelf in our warehouse in Charlotte, NC. Buying in bulk also

brings the cost down, so we can pass them along at prices that may

surprise you for a premium European brand. When you look at the

specification of our discs vs. the competition, AP's racing heritage,

and the longevity you'll get from them, they are an incredible

bargain. Most of the competitive discs on the market are 48 vanes or

less, weigh more, have less optimized vane design, inferior metallurgy,

and have never been proven under the same conditions as the AP Racing

discs. Many of our race customers have run an entire season or more on a

single set of discs.

We also stock spare brake pads, pistons, seals, springs, and other hardware components so they're available when needed in a pinch.

Q: Will your brake kit clear my wheels without a spacer?

A: Essex cannot guarantee wheel fitment, and we will not be held responsible for a kit not fitting behind particular wheels.That said, we do offer some tools to assist our customers in this area.

We provide a downloadable wheel fitment template or every brake kit we sell. All you have to do is download it, print it to scale (check with a ruler), and stick it inside the wheel in question. Another option would be to have your wheel seller check for you using the template.

If we've had a customer confirm fitment of our kit with a particular wheel, we also list it in the wheel fitment tab on the product detail page for that particular kit. Again, these details are provided by customers, and we cannot guarantee their validity.

Q: Which side of the vehicle is left, and which is right?

A: If you're sitting in the driver seat of a USDM vehicle, you are on the left side/driver side.The other side is the passenger side/right side.

Q: Which disc is the left hand disc, and which is the right?

A:To illustrate further

Q: How do I bed-in / burnish my new pads and discs?

A: We have a detailed video that goes into the burnishing procedure in great depth. Please see our video "How to Bed-in Brake Pads and Rotors."

Q: I have a vibration or judder when I press the brake pedal. How do I get rid of it?

A: What you are experiencing is most likely an uneven brake pad deposition on the disc face.What that means is brake pad material is stuck to the face of your brake disc in splotches and patches. On a properly bedded/burnished disc, that material is evenly distributed around the disc.If it is unevenly smeared on the disc, high spots are created on the disc face. Every time you press your brakes and the pads come in contact with that high spot, you feel it as a judder through the brake pedal and/or steering wheel. Our recommendation is to first try and remove those high spots by driving an aggressive set of race pads cold. When you drive race pads cold, they scrape material from the disc, rather than depositing material on the disc.In this manner you can "clean" your discs. To see this process in action, check out our video "Swapping Between Street and Race Brake Pads." To help prevent uneven pad deposits in the future, never come to a complete stop and leave your foot on the brake pedal after heavy brake use (coming off the track). Also, do not engage your parking brake under those conditions.

Q: Why do my brake discs feel slimy, and how do I clean this oil off of my brake discs?

A: The oil is to keep the discs from rusting while they are sitting in a warehouse and in transit.Washing them with soap and water will be sufficient to get them clean and prepped for install.

Q: Do I need to buy new discs, or machine my discs when I buy new pads?

A: No. As long as your discs are not below their designated minimum thickness, or cracked beyond use, you can run them with your new pads. Machining the discs is not required. That said, if you're switching to a different pad compound, it's usually a good idea to scrub your new discs first, to remove the old pad material from them.You can see details on this procedure in our video "Swapping Between Street and Race Brake Pads."

Q: My brakes squeal when I stop…what can I do?

A: One of the most common causes of brake squeal is poorly bedded discs.Please see our video "How to Bed-in Brake Pads and Rotors."

Q: I'm seeing a bit of tapered wear on my pads. What can I do?

A: It's extremely difficult to have zero pad taper. Longitudinal taper (end-to-end) is the most common.This phenomena is when the material burning off of the pad face gets trapped under the back edge of the pad, which causes them to wear unevenly. Our brake kits have differential piston bores (pistons of different sizes) to combat this issue, but we still sometimes see mild cases of it.

A: What does leading and trailing mean?

Q: Using a front brake kit as an example, a leading caliper is one that sits in front of the front axle, closest to the front bumper. A trailing caliper is one that sits behind the front axle, closest to the passenger compartment.

Q: I live in (country outside of North America).Can you ship me one of your brake kits?

A: Due to contractual obligations with AP Racing, Essex only ships big brake kits to physical addresses inside North America, or to a territory in which there isn't currently an authorized AP Racing distributor. To see if there is an authorized AP distributor in your area, please click here. Your other option is to contact one of our current authorized dealers in the USA and see if they can help you.

Q: Do you offer discounts to internet forum members, or to members of clubs and organizations such as NASA, SCCA, PCA, BMWCCA, etc.?

A: Due to the narrowly targeted nature of our products, just about every customer of ours is in some way involved with one of these organizations. If we offered this type of discount, we'd essentially be discounting to every single customer. That is not a policy that would allow us to stay in business and keep bringing you the best brake products on the market for your car!

Also, since we sell to wholesale customers, we cannot undercut them on price. As such, all products we sell to retail customers are sold at the retail prices listed on our website.

Q: Do you offer sponsorships?

A: AP Racing is frequently recognized as the #1 brake supplier in professional racing today. Top teams from around the world in F1, Sprint Cup, ALMS, WRC, etc. pay a premium for AP Racing brakes because they are the best brake products available at any price. To receive any type of consideration for a sponsorship, you would have to provide an extraordinary amount of media coverage, and bring tangible benefits to the AP Racing and Essex brands.

From time-to-time we do have retail customers test new products.In those cases we would offer a small discount for providing feedback on those products.

Q: Can I drive with your brake kit in foul weather conditions?

A: Any aftermarket BBK will require similar maintenance and present the

same problems in foul weather conditions. The most vulnerable area for

problems is the attachment point between the iron disc and aluminum hat.

That's why you don't see a whole lot of OEM two-piece discs using an

aluminum hat. Over the years many OEM's use a dual-cast iron design with

as few moving parts as possible. What happens is, that road salt and

other gunk gets wedged between the hat and iron disc ring, and it is

essentially impossible to remove short of taking the disc apart. The

salt eats away at the aluminum hat, eventually flaking, chipping, etc.

Again, this is a problem that will be encountered on ANY aftermarket big

brake kit. Also, the same sort of things happen with the caliper

brackets on just about ANY aftermarket BBK. They're almost all anodized

aluminum.

Q: Are your big brake kits road legal?

A: All of the brake kit Essex

sells are designed for off-road use only.If you read the fine print on

any aftermarket big brake kit, from any manufacturer, you'll find the

same thing...for off-road use only.We don't design our brake kits to

meet any government standards, as

there is no such standard or requirement in the USA for brake kits.There are however some regulations on brake hoses/lines and brake fluid.All stainless steel brake hoses and brake fluid that Essex sells are DOT compliant. Please read below and click the link for more details and info.

There are several federal organizations involved with the regulation of vehicle parts in the USA, but the two most relevant to the products we sell are the Department of Transportation (DOT) and the National Highway and Transportation Safety Administration (NHTSA).

NHTSA is the U.S. government agency responsible for implementing and enforcingthe National Traffic and Motor Vehicle Safety Act of 1966, as amended, 49 U.S.C. Chapter 301 (the Vehicle Safety Act),and certain other laws relating to motor vehicle safety. Under that authority, NHTSA issues and enforces federal motor vehicle safety standards (FMVSS) that establish minimum safety performance requirements for motor vehicles and for 13 items of motor vehicle equipment(i.e., “regulated motor vehicle parts”). Regulated motor vehicle parts include tires, rims, brake hoses, brake fluid, seat belt assemblies, lighting equipment, glazing, motorcycle helmets, child restraints, compressed natural gas containers, rear impact guards for trailers, platform lift systems for the mobility-impaired, and triangular reflective warning devices.

To be lawfully imported, a new or used regulated motor vehicle part must, as originally manufactured, conform to the version of the applicable FMVSS in effect on the date of manufacture and be so certified by its manufacturer.In most instances, certification of compliance with the applicable FMVSS for regulated motor vehicle parts is shown by the symbol “DOT” either inscribed on the part in a prescribed location, or placed on the outside of the container in which the part is shipped.The full text of each FMVSS for motor vehicles and motor vehicle equipment appears in49 CFR 571.Most of the standards listed below are vehicle standards. Compliance with a vehicle standard is certified by the vehicle manufacturer and not by the manufacturer of the vehicle system or component that is addressed by the standard. Some of the standards establish minimum safety performance requirements for motor vehicle equipment. Those standards are marked in the list below with an asterisk(*). The manufacturer of equipment that is subject to a standard must certify the equipment’s compliance with the standard.

You can see full details here: http://gsi.nist.gov/global/docs/motor_vehicle_part...

Can the manufacturer of my car deny a warranty claim because your brakes are on it?

The information below is provided by SEMA, and can be found on their website (www.sema.org) under “Federal Warranty Laws.” You can also Google “The Magnuson-Moss Warranty Act (15 U.S.C. 2302(C).”

The Magnuson-Moss Warranty Act is a federal law that regulates warranties to protect consumers.It essentially states that the use of an aftermarket part alone is not cause for denying the warranty. However, the law's protection does not extend to aftermarket parts in situations where such parts actually caused the damage being claimed under the warranty. Additionally, consumers are advised to be aware of any specific terms or conditions stated in the warranty, which may result in its being voided. The law states in the relevant section:

“No warrantor of a consumer product may condition his written or implied warranty of such product on the consumers using, in connection with such product, any article or service (other than article or service provided without charge under the terms of the warranty) which is identified by brand, trade or corporate name....” (15 U.S.C. 2302(C)).

Q: Do your brake kits come with a warranty?

A: No.The disclaimer of warranty below appears on the first page of the install manual inside the box of every AP Racing by Essex Kit.That said, if you order a big brake kit and there is something blatantly wrong when you open the box (the wrong caliper is inside, etc.), we will do everything in our power to correct the situation immediately.We have stringent quality controls in place to prevent such a situation from occurring, and in all cases, multiple employees handle and check our products for issues before they go out the door.

Disclaimer of Warranty

By purchasing this product and opening this box, purchaser expressly acknowledges, understands and agrees that they take, select and purchase this brake system, parts, and equipment from Essex Parts Services, Inc., its affiliates, suppliers, distributors, and agents (collectively, “Essex”) “as is” and “with all faults.” The entire risk as to the quality and performance of this brake system, parts, or equipment is with the purchaser. Should the goods prove defective following their purchase, the purchaser assumes the entire cost for all necessary servicing or repair or any resulting liability. Essex is not responsible for any damage, consequential or otherwise, for equipment failure or mal-performance after installation. Essex makes no warranties whatsoever, expressed or implied, oral or written, to purchasers or any users of these products. Essex expressly disclaims any implied warranty of merchantability or warranty of fitness for a particular purpose, including fitness of these systems, parts or equipment for racing or road use. No warranty or representation is made to the product’s ability to protect the user from injury or death. The user assumes all risk.By purchasing this product and opening this box, purchaser expressly affirms that they are relying upon their own skill and judgment in selecting and purchasing these goods as suitable for purchasers’ intended use. Purchaser understands and agrees that no officer, director, salesman, distributor, or agent of Essex has any authority to make any statement contrary to the terms of this disclaimer and agreement. On the contrary, Essex disavows any statement contrary to what is written above.

See this kit in action in our Customer Gallery.