Track and Racing Brake Pad Owner's Guide

03.27.2019

By Jeff Ritter, 3/25/19

If you asked me if racing brake pads should come with an owner's manual fifteen years ago, I would have definitely laughed at you. How complicated could those little blocks of metal possibly be? However, after twenty years of track driving and talking with thousands of brake customers, I can tell you that brake pads are incredibly complex. The automotive forums for every popular sports car are littered with questions about racing brake pad usage. "Why are my pads tapering or cracked? How long will they last? When should I get rid of them?" In this article we'll look at the common issues track enthusiasts face while managing their brake pads.

Terminology

Let's review some standard terminology associated with brake pads:

Backing Plate- The steel plate to which a friction puck is bonded.

Bedding-in- The process of heating a brake pad to a desired temperature, at which a thin layer of pad material adheres to the disc face. The process causes chemical changes in the brake pad material.

Burnishing- A

mechanical process during which the surface of the brake pad and the

surface of the disc face are rubbed together until the faces of both are

leveled and mated together. Because bedding-in and burnishing frequently occur during the same processes, the two terms are often used interchangeably.

Friction Puck- The pad compound or friction material itself, which is bonded to a backing plate.

Shim-

A thin plate attached to back of the backing plate, designed to reduce

NVH (Noise/Vibration/Harshness). It's extremely rare for a racing pad

to use shims, since noise abatement is a very low priority for track

use, and they can cause increased pedal travel at track temperatures.

Pad Length- The distance from one end of the pad backing plate to the other. Pretty obvious, right?

Pad Width / Height- Things

get a little less obvious after length. Our team typically doesn't use

the term 'width' when discussing pads. We use the word 'height' to

describe the distance from the top edge of the pad backing plate that is

visible from the top of the caliper, down to the lower edge of the

backing plate that sits closest to the wheel hub.

Pad Radial Depth-

Related to height, a pad's radial depth is the height of the friction

puck itself, and is a key determinant of whether a pad will rest

properly on a given brake disc. A brake disc's radial depth is the

distance from the disc's outer edge (OD) to the disc's inner edge (ID).

Ideally, the pad's radial depth will match the disc's radial depth. If

the pad's radial depth is too small, it will leave an unswept ring on

the disc face near the hat attachment point, potentially causing a

temperature gradient and premature cracking. Conversely, if the pad's

radial depth is too tall for the intended disc, the bottom of the edge

can interfere with the disc hat and/or attachment hardware. Like

thickness, many manufacturers offer the same basic pad shape in multiple

radial depths, so be sure to carefully evaluate all a particular pad's

specs before choosing one for your calipers.

Pad Thickness-

Thickness is the distance from the friction surface that contacts the

disc, to the part of the backing plate that touches the caliper pistons.

Most manufacturers list the combined thickness of both the friction

material and the backing plate when quoting thickness, not just the

thickness of the friction puck. When we say 25mm thick pad, we mean the

entire pad including the backing plate is 25mm thick. Many pad

manufacturers offer the same pad shapes in multiple thicknesses. Make

sure that the caliper and disc you're using can accommodate the pad

thickness you're considering.

Pad Volume-

Length x Height x Thickness of the friction puck (approximately). The

larger the pad volume, the more heat that pad can absorb. That said,

pad volume can come in different forms, and is dependent on the specific

goals of the overall brake system. For example, because carbon ceramic

(CCM) brake discs don't conduct heat well, they are designed with a

large surface area to spread and radiate heat. As such, the

corresponding pads tend to be very tall, but, typically not very thick

(14-16mm is typical). Conversely, the complex internal vane patterns

and superior material heat conductivity of iron racing brake discs are

more adept at pumping air and maintaining lower temperatures. They can

therefore use a shorter radial depth on both the disc and pad. Pads

mated to iron discs can increase volume and heat capacity via thickness.

In endurance racing situations where pad longevity is important, pad

thicknesses of 25-30mm are the norm.

Pad Surface Area-

Length x height of the friction puck surface. Many people mistakenly

place too much emphasis on a pad's surface area, rather than its volume.

As described above, in some applications a large pad surface area is

used to spread heat out across the pad's face. In most cases however,

overall pad volume is the more important consideration when determining a

pad’s heat capacity, potential lifespan, etc.

Now that you know a

little bit more about race pad construction and preparation, let's move

on to how you can get the most out of these interesting little hunks of

metal.

Racing Pad Construction

Brake pad compounding is a bit mysterious. You can think of the engineers who formulate pad compounds as part scientist, part artist, and part chef. Manufacturers combine an incredibly wide array of raw materials to create their friction materials, always with a specific goal in mind. While street pads are usually designed with low noise and cold bite in mind, race pads are designed for stability and consistency at extremely high temperatures.

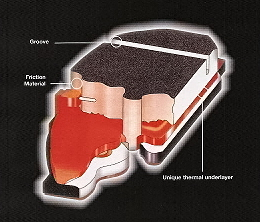

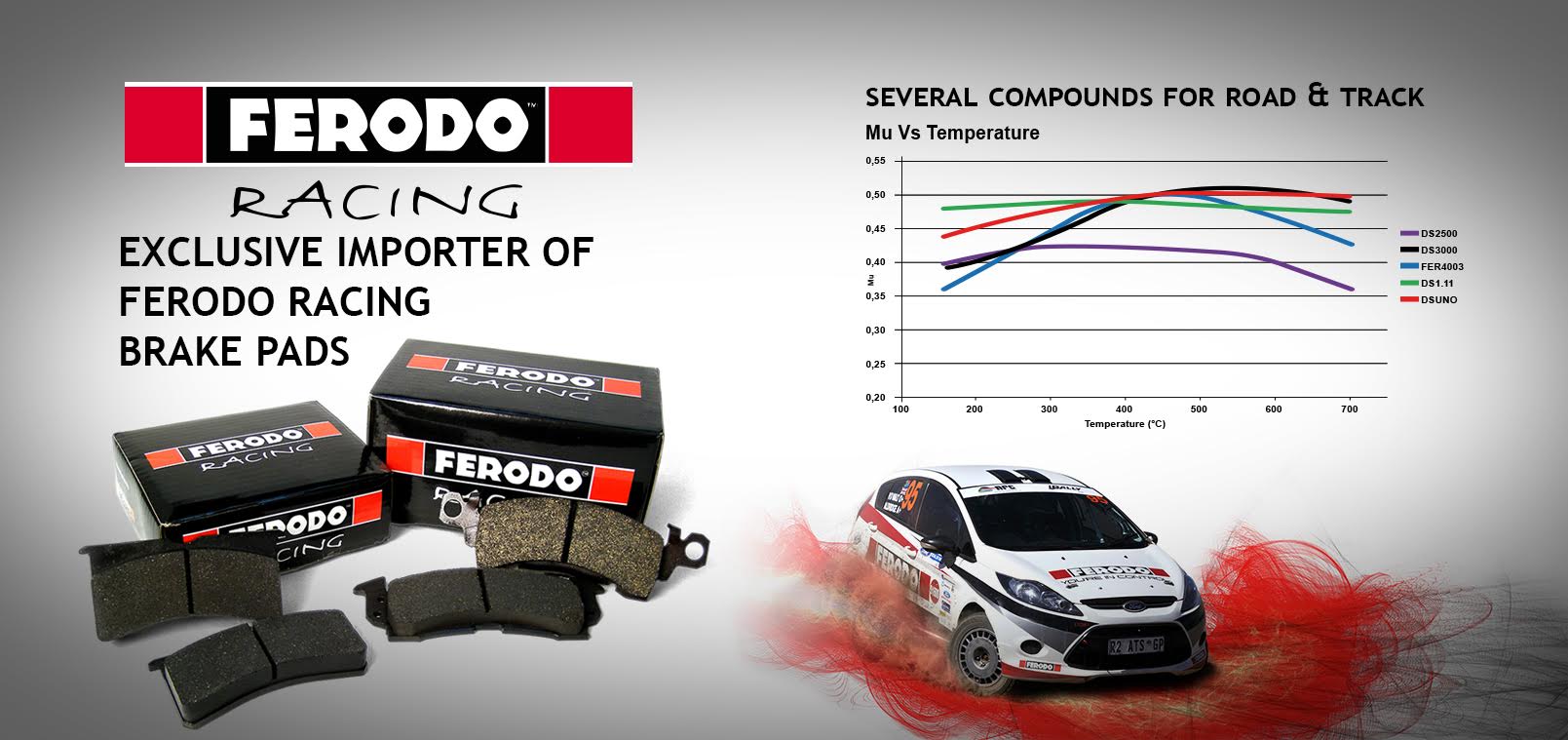

Racing brake pads frequently contain up to 35 ingredients, adhesives, fillers, friction modifiers, resins, and lubricants. In professional-grade racing pads, such as the Ferodo DS series of pads, the primary pad compound sometimes sits atop a thermal underlayer. The thermal underlayer is a thin mix of material pressed between the backing plate and the friction material. The underlayer helps ensure proper binding of the pad compound to the plate, but is specifically designed to prevent heat penetration through the backing plate and into the caliper pistons and brake fluid.

The vast majority of racing pads use some type of adhesive to bond the friction material/underlayer to the backing plate. Top-tier race pads typically also use some form of mechanical retention as an added safety feature to prevent the friction puck from de-laminating (falling off the backing plate). As an example, the brass stud mechanical retention system below is employed by Ferodo.

Racing pads also frequently have vertical grooves cut into their face. Just like your driveway or the highway, these expansion grooves provide space for the materials to expand and contract without fracturing as the pads are repeatedly heated to, and cooled from, track temperatures.

One of the final processes in race pad manufacturing is called “scorching”. When pads are formed in a press, some quantity of binders or resins remain on the friction surface of the pad. During scorching, the friction surface is blasted with flames in an oven to burn out some of those surface resins. If those surface resins are not removed via scorching (and a proper bed-in), those resins can melt or vaporize during any initial hard braking events, leading to an unstable friction level. This phenomenon is frequently referred to as 'green fade' (green as in “new”). One can think of scorching as an incomplete form of bedding, or the step prior to bedding the pad on a brake disc. Scorching improves the likelihood of a successful bedding process by reducing the chance of uneven pad deposits on the disc face. Many race pads today are being marketed as "pre-bed," but unless the pad has literally been run on a disc face, they are only scorched.

Predicting Pad Wear Rates

One of the first questions enthusiasts ask when shopping for track pads is, "How long will they last?" Due to the laundry list of factors involved, that's an impossible question to answer. Vehicle power and weight, weight distribution, tire choice, track configuration, driving style, brake disc material and groove pattern…the list of factors that contribute to pad wear is lengthy.

Something most people don't consider however, is that they may not actually want the hardest, most abrasive, longest-wearing brake pads available. While tires grip the tarmac and slow the car, your brake system's primary function is to convert the energy of the spinning disc into heat. That is accomplished via the friction generated by your brake pads rubbing on your brake discs. When heating two hunks of mostly metal to 1500°F and rubbing them together vigorously, something is going to wear. The softer of the two materials being rubbed together will wear more quickly. An incredibly hard, abrasive brake pad is going to devour gray iron brake discs, particularly when run cold. If you're running a $300 set of pads, on a $1000 set of discs, which one would you like to burn through more quickly? Always remember that both brake pads and discs are consumables.

A complicating factor when considering pad and disc wear is the pad transfer layer. A pad transfer layer occurs when a brake pad is heated to a certain temperature, and an ultra-thin layer of friction material transfers to the disc face. The goal is to gradually bring the pad to that temperature and build an even transfer layer on the disc face in a controlled manner. That is accomplished through the bed-in procedure (see our video on that topic here). When heated, pad material is constantly being transferred back and forth from the disc face to the pad face.

Inspecting Pads for Wear

As a rule of thumb, the less pad material you have remaining, the faster they will burn. Pads wear at a faster rate the closer they get to the end of their service life. A full depth pad has more mass/volume. As such, it can absorb more heat than a thinner pad. For example, let’s say that when you start with brand new pads you’re using up 1mm of friction material per track session. By the time 80% of the friction material is gone, you may be wearing 1.5-2.0mm of friction material per session. Pad wear accelerates as the pad gets thinner. The closer you get to the backing plate, the more frequently you need to be checking them.

Inner pads tend to wear more quickly than outer pads for the typical HPDE, time trial, or club race car. That's because there tends to be less airflow to the inner pad area. A factory brake debris/splash shield is sometimes left in place, which holds heat against the inner disc face and blocks cooling air. If brake ducting is being employed, it frequently isn't properly implemented. In many cases that is simply due to packaging issues at the front of the car. There's no room to implement a professional-grade duct solution that flows adequate air. because of wiper washer bottles, oil coolers, etc., or the marketing team just wanted an air inlet in the wrong pressure zone! As such, you need to keep an eye on both the inner and outer pads, because they will wear at different rates. The inners typically wear faster than the outers, so just peeking through the wheel spokes to assess pad wear doesn’t cut it, particularly when the pads are getting low. It’s very important that you look on the inside of the caliper as well.

Looking through the wheels at the outer pad doesn't get it done. You need to watch the inner pads as well!

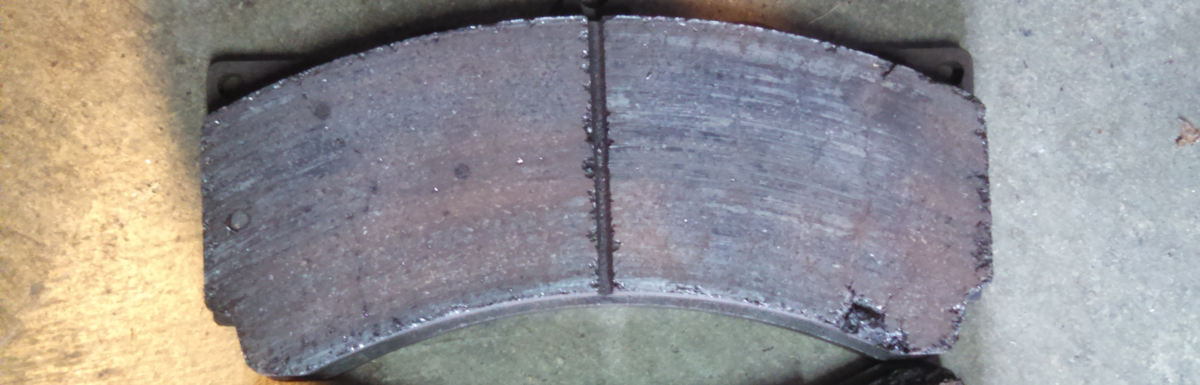

Pad Taper

You’re always going to have some taper, and a few millimeters of taper is quite low and completely normal. In racing situations, we see as much as 10mm of taper, and the taper is not equal from pad to pad. Again, pad taper is completely unavoidable. We see it on every car, with every brake kit, from every manufacturer. We see it both radially (top-to-bottom) or longitudinally (end-to-end). We almost always see slightly different wear characteristics on the left and right side of the car based on track configuration. We see it all levels of racing, including NASCAR Sprint Cup. One reason it occurs is because of uneven temperatures at the leading edge of the pad and the trailing end. The leading edge will always run hotter and wear faster than the trailing edge. The trailing edge floats a bit on pad material that is torn from the leading edge and pulled back towards the trailing edge. The longer the pad is, the more pronounced the taper tends be. If you look at a short four piston pad vs. a longer six piston pad, the six piston pad will always have more taper all else held equal. The pistons in our AP Racing calipers have differential bores (pistons are different sizes) designed to combat this issue. The piston on the leading edge is smaller to apply less pressure, while the trailing piston is larger to apply more pressure, which helps even out the wear. It’s pretty much impossible to completely eliminate all taper however. The solution to get more even wear out your pads is to occasionally flip the pads in the calipers from inner to outer, so that the edges that were leading last time are now trailing, and vice versa. Doing so occasionally also gives you a chance to inspect the pads and make sure they aren’t getting too thin.

Below is a good example of longitudinal pad taper. Rotate your pads to squeeze the most life out of them.

Driving Aids and Pad Wear

Just about every high-tech sports car today employs some form of driver aid that attempts to keep your car on what it believes is your intended path.Every manufacturer uses their own unique acronym to describe these systems, and some examples would be AYC (Active Yaw Control), DSC (Dynamic Stability Control), DPC (Dynamic Performance Control), PTV (Porsche Torque Vectoring), Active Handling, Drift Mode, etc.If you use any of these driving aids (frequently referred to as nannies), you will see greater brake pad wear than if you were driving with them completely disengaged.Why?Because these systems leverage your vehicle’s brakes to adjust your car’s direction of travel.They use a sensor array to measure items such as steering angle, yaw-rate, individual wheel speeds, and lateral acceleration, and then the car selectively applies individual front or rear brakes to alter the vehicle’s path.The result can be hyperactive braking, which can generate a tremendous amount of heat and accelerated brake wear.

The most common manifestation of this technology we see is extreme pad wear on the inside rear brakes. In this case, inside means the side of the car closest to the apex of the turn.In a right-hand turn for example, the car would drag the passenger side rear brake to help the car pivot (yaw) through the turn.The more active or intrusive the system is, the greater the resulting pad wear. The result is that the brake pads in one caliper wear out much more quickly than the other three corners of the car.

If you want the least and most even pad and disc wear possible, learn to drive your car on track without driving aids.It may slow you down a bit initially, but it will ultimately make you a better driver, and your brakes will thank you! If you drive with aids engaged, be prepared to see uneven brake wear on one or more corners of your car.

How Thin is Too Thin?

A general rule of thumb for determining when to replace a track pad is when the pad friction material thickness equals, or just less than, the thickness of the backing plate. At that stage, you should remain extremely vigilant, because the pads will start burning at a faster rate. If the inners are burning faster than the outers, or if a large amount of pad taper is present, you may be shooting sparks when your hard steel backing plate makes direct contact with the soft iron brake disc. The safe bet is to always have a spare set of pads on-hand, so you don’t miss any track sessions.

This pad was worn down to the backing plate, and then some!

Breaks, Cracks, and Fractures

It’s not unusual to see some edge crumbling with race pads. Small chunks of material breaking off from the pad edges is not a crisis and does not indicate a product failure. If large pieces are coming off, or if the pad material separates completely from the backing plate, then you have a problem. That said, when you get down to a few mm of pad material left after repeated track thrashings, all bets are off. Sometimes you'll see crumbling, cracking, etc. Repeated heat cycles make them more fragile than they were when new. If you took them down that far, they’ve already done what they were designed to do. Calling the pad manufacturer for a refund after ten track days is poor form, and it isn’t fair to the pad manufacturer or seller. Brake pads are a consumable, just like tires and gasoline.

Some edge crumbling like this isn't a problem:

Shake, Rattle, and Squeal

Track pads are not designed to be silent. They’re designed to generate friction at extremely high temperatures, and NVH is not a concern. If you want a silent pad, go with a mild street compound, and save your race pads for the track. If you are switching between track and street environments on a regular basis, check out our videos titled, “How to Swap Between Street and Race Brake Pads” for some helpful tips on pad noise management.

If your brake pads are slightly loose in your aftermarket caliper, you shouldn’t be surprised. That allows the pads space to expand when they reach searing track temps. A little bit of rattle or pad movement with racing calipers is completely normal. Some aftermarket caliper manufacturers provide some form of spring retention to prevent pad movement and noise, while others do not. Also note that when shifting from forward to reverse and back, the pads may also ‘clunk’ against the abutment plates when they shift from one end of the caliper to the other.

Handling pads

One final note, which may not even apply to your situation. Be careful when handling pads, particularly after they've been run on the track. We have a lot of customers who frequently swap pads when going from full track use to AutoX, etc. I've seen them drop their race pads on the asphalt, use them to lever their caliper pistons back into the bores, etc. They aren't indestructible. As pads are cooked over and over on track, some of the binding agents, adhesives, fillers, etc. in the pads start to break down. As such, they need to be handled carefully and not used as tools!

Conclusion

Hopefully this article provided you with some insight on how to better manage your track brake pads. These seemingly innocuous little lumps of metal can provide their owner with either great frustration at the track, or great joy. Our hope is that you're now armed with the knowledge to pursue the latter!

Customer Comments:

No comments posted yet

You must be logged in to leave a Comment